W. NR. 1.2312

Characteristics

Chrome-manganese-molybdenum steel for hardening in air or in oil with very good hardenability and good firmness during the heat. It is well-workable during the heat and due to an increased content of sulfur well-workable both in the soft-annealed state and the heat-treated state. The steel has good polishability, it can be cemented in the bath or in gas and also put on the hard-chrome.

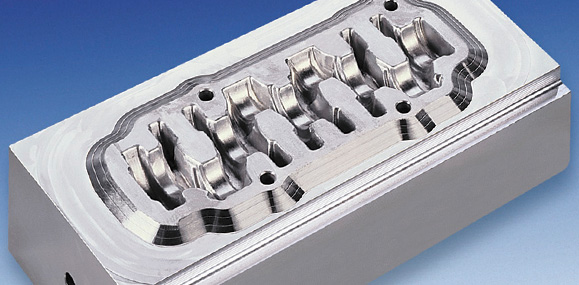

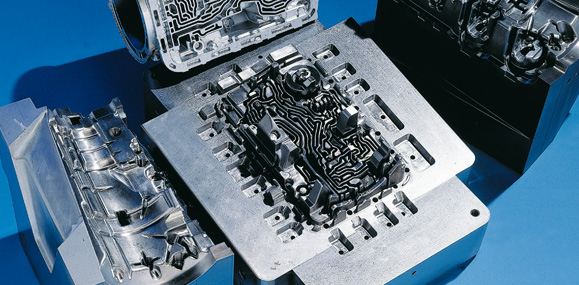

Suitability

Tools for processing of plastic substances such as big and middle molds, forming frames for casting of plastic substances and metals under the pressure. For less demanding tools there is a possibility to use the steel in the heat-treated state at 950 up to 1100N/mm2 without further heat treatment.

Chemical composition of steel W.Nr. 1.2312

| Steel grade | Chemical composition in % | Hardness in state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN 40CrMnMoS86 | 0,35-0,45 | 1,40-1,60 | 0,30-0,50 | 1,80-2,00 | 0,15-0,25 | 0,030 | 0,05-0,10 | 235 | 51 | ||||

| ČSN není | |||||||||||||

Heat treatment of steel W.Nr. 1.2312

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 850-1050 | Cool slowly in dry ash or thick cross-sections in the furnace | |

| Soft annealing | 760-780 | Warm few hours (according to the size of object), mostly four hours are enough and cool slowly in the furnace | |

| Annealing to lower tension | 600-650 | Warm 1 to 2 hours and cool slowly in the furnace | |

| Hardening | 840-880 | Cool in oil or in air at 180-220 °C | |

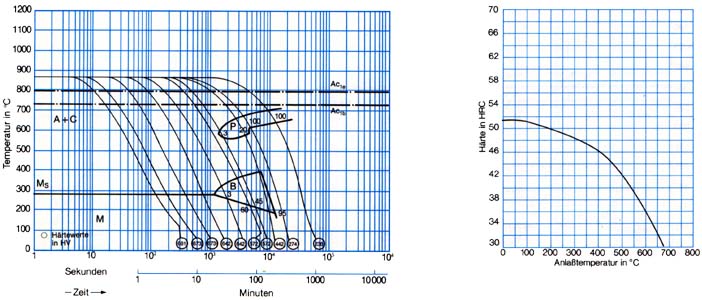

| Tempering | 640-680 | Cool in air, the degree of tempering is set by hardness and toughness of instrument according to the tempering chart | |

Note

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 51 | 50 | 48 | 46 | 42 | 36 | 28 |

| N/mm2 | 1730 | 1670 | 1570 | 1480 | 1330 | 1140 | 920 |

Graph

Product range

Round bars: D20 - D303

Metal plates: s.20 - s.350

Blocks: 610x1600, 810x1200

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.