W. NR. 1.2101

Charakteristika

Chrom - křemíková ocel se střední prokalitelností ke kalení v oleji, velmi dobrá houževnatost při poměrně vysoké tvrdosti, dobrá odolnost proti dynamickému, střídavému namáhání a namáhání údery, velmi dobrá pružnost a odolnost proti opotřebení (i ve stavu tepelně nezpracovaném), dobrá tvárnost za tepla a dobrá obrobitelnost v žíhaném stavu.

Vhodnost použití

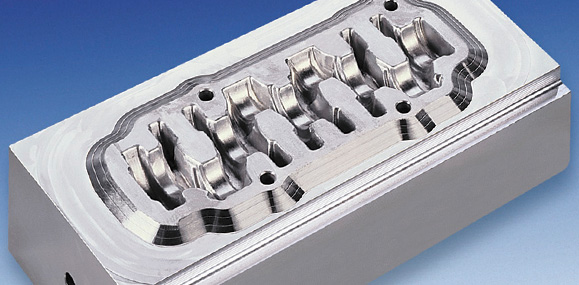

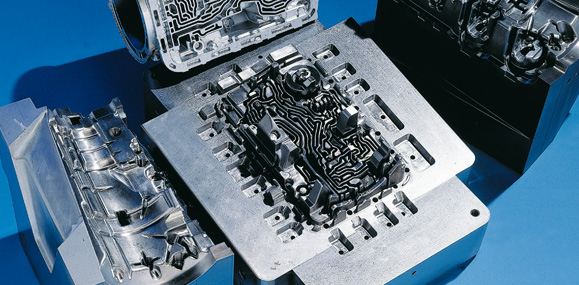

Nástroje pro stříhání za studena tj. přestřihovací, prostřihovací, ostřihovací a děrovací nástroje, nože nůžek pro stříhání materiálů větších tlouštěk. Nástroje řezné na obrábění dřeva např. hoblovací nože, frézy, vrtáky, dlabací řetězy aj. Ruční nástroje tj. ruční a pneumatické sekáče, šroubováky, klíče aj. Nástroje upínací např. kleštiny. Dále na formy např. vyhazovače, závitové kolíky pro tváření plastických hmot, formy na lisovaní cihel a šamotového zboží. Nástroje na drcení a mletí - menší kladiva a čelisti drtičů.

Chemické složení oceli W.Nr. 1.2101

| Značka oceli | Chemické složení v % | Tvrdost ve stavu | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Žíh. na měkko | Zušlechtěném | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN 62SiMnCr4 | 0,58-0,66 | 0,90-1,20 | 0,90-1,20 | 0,40-0,70 | 0,030 | 0,030 | 225 | 61 | |||||

| ČSN 19 452 | 0,55-0,65 | 0,60-0,90 | 1,50-1,90 | 0,70-1,00 | 0,35 | 0,030 | 0,035 | 230 | 58 | ||||

Tepelné zpracování oceli W.Nr. 1.2101

| Způsob | Teplota [°C] | Postup | |

|---|---|---|---|

| Kování | 850-1050 | Pomalu ochlazovat na klidném vzduchu nebo lépe např. v suchém popelu nebo v jiném tepelně izolačním materiálu | |

| Žíhání na měkko | 700-750 | Několik hodin prohřát (podle velikosti předmětu), většinou stačí 4 hodiny a pomalu ochlazovat v peci | |

| Žíhání ke snížení pnutí | 600-650 | 1 až 2 hodiny prohřát a pomalu ochlazovat v peci | |

| Kalení | 830-860 | Olej nebo teplá lázeň 180-220 °C | |

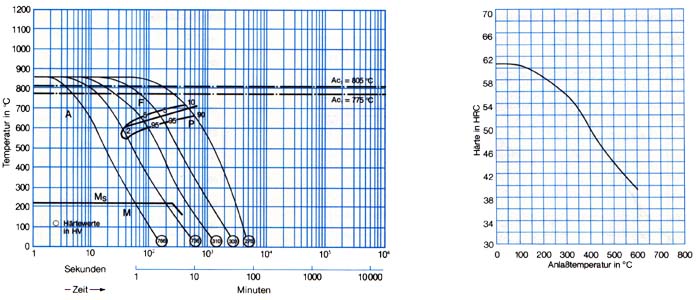

| Popouštění | 240-350 | Ochlazovat na vzduchu, stupeň popouštění se řídí tvrdostí a houževnatostí nástroje dle popouštěcího diagramu | |

Poznámka

- Vhodná pružinová tvrdost je asi 45-55 HRC.

Tabulka popouštěcích hodnot v závislosti na tvrdosti:

| °C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 61 | 59 | 56 | 50 | 45 | 40 |

Graf

Dodávaný sortiment

Kruhové tyče: D6 - D215

Bloky: 410x810

Z výše uvedených rozměrů Vám nadělíme jakékoliv polotovary. Další rozměry, mimo uvedené skladové zásoby, s námi konzultujte.