HP1

Characteristics

HP1 is an unalloyed CR-Mo-V steel with a reduced content of Mo (in comparison with TQ1) with the admixture of Nb for the refinement of structure. It excels in a comparable thermal resistance and toughness as material TQ1 while the reduced content of Mo influences the price of material at the same time. HP 1 is only produced by technology ESU, due to this the material has a high cleanness and a low content of trace elements. It is delivered in the soft-annealed state of max. 230 HB.

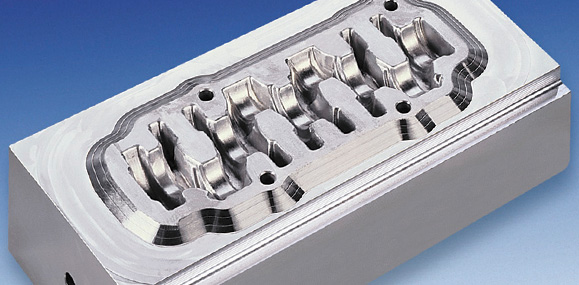

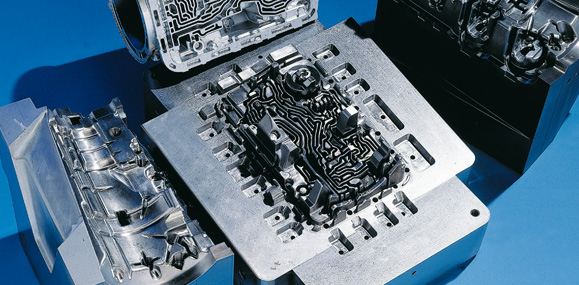

Suitability

HP 1 is appropriate for using in the following applications during a very high stress: pressure casting, extrusion, stamping, hot mechanical working. It is not appropriate for polished parts in comparison with material TQ 1.

Chemical composition of steel HP1

| Steel grade | Chemical composition in % | Hardness in state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| HP1 | 0,35 | 0,30 | 0,20 | 5,20 | 1,40 | 0,55 | 0,12 | 0,003 | 230 | 52 | |||

Heat treatment of steel HP1

| Way | Temperature [°C] | Procedure |

|---|---|---|

| Forging | For all the heat treatment of steel GSF we recommend the company BODYCOTE. | |

| Soft annealing | ||

| Annealing to lower tension | ||

| Hardening in oil or in air | ||

| Tempering |

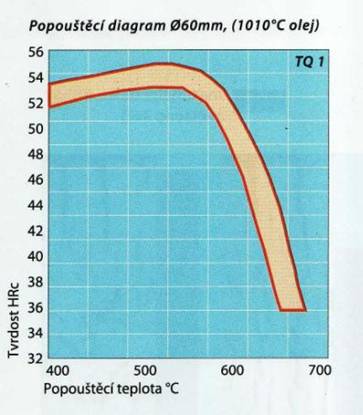

Tempering chart

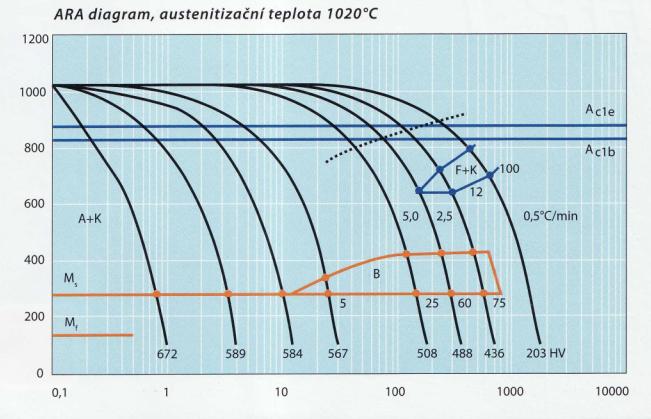

ARA diagram

Product range

Round bars: D102 - D605

Blocks: 510x810

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.