W. NR. 1.2358

Characteristics

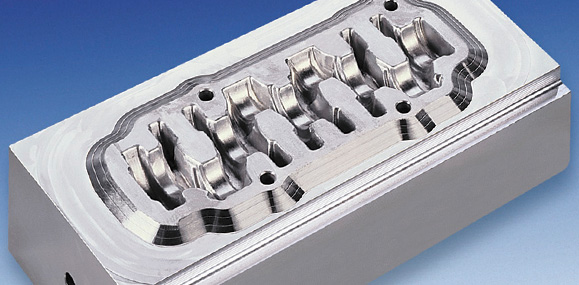

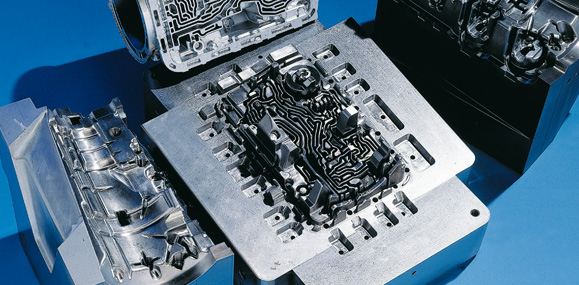

Chrome-molybdenum-vanadium steel is characterized by high toughness and good resistance to the wear. Further the steel has good hardenability and good dimensional stability after hardening and tempering. The steel can also be well welded and well polished. The toughness of quality 1.2358 reaches higher values than by other steels for cold work (1.2842, 1.2363, 1.2080, 1.2379, 1.2436). An excellent combination of toughness and resistance to the wear enables the usage of quality 1.2358 also for different pressing and injection applications during plastics processing.

Suitability

Steel W. Nr. 1.2358 can be used both for cold work and for molds for plastics. In case of using for cold work we can talk mainly about these applications: cutting and mechanical working (also materials of bigger thicknesses), deep drawing, punching, rolling, production of shear blades, more complicated tools for cold work. In the area of molds for plastics the steel can be used e.g. for molds for large series, molds for plastics with additives, tools for plastics stamping etc.

Chemické složení oceli W.Nr. 1.2358

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN 60CrMoV18-5 | 0,6 | 0,8 | 0,35 | 4,5 | 0,50 | 0,2 | 240 | 64 | |||||

Heat treatment of steel W.Nr. 1.2358

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Soft annealing | 860 | Warm to 860 degrees and cool slowly in the furnace at the speed of 20 degrees an hour up to 770 degrees. Then cool at the speed of 10 degrees an hour up to 650 degrees and then cool slowly in air. | |

| Annealing to lower tension | 650 | After rough processing warm the semi-finished product up to 650 degrees and remain at this temperature for 2 hours. Then cool slowly in the furnace up to 500 degrees and finally cool slowly in air. | |

| Hardening | 950-970 | Pre-heat up to 600-750 degrees, austenitization temperature 950-970 degrees. | |

| Tempering | 180 | Temper twice a minute at 180 degrees with the intercooling to the room temperature. Endurance 1hour/20 mm of thickness but at least 2 hours. | |

Product range

Blocks: 310x610, 355x610, 405x610

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.