TENASTEEL ®

Characteristics

Material TENASTEEL® is a technologically advanced material designed for demanding applications of cold working of metals. By using the innovative technology of production, the high cleanness of macrostructure of material, which together with precipitates of titanium creates the optimal matrix for coating tools, was achieved. By lowering the content of chrome against the oil 1.2379, the workability of material has been improved. On the whole, TENASTEEL® excels against the steel 1.2379 by higher hardness in the pressure, it resists abrasion of external environment more effectively and with the higher temperature of tempering it is suitable for a broader spectrum of coating technologies. Material TENASTEEL® is delivered in the annealed state with the maximum hardness of 250HB.

Suitability

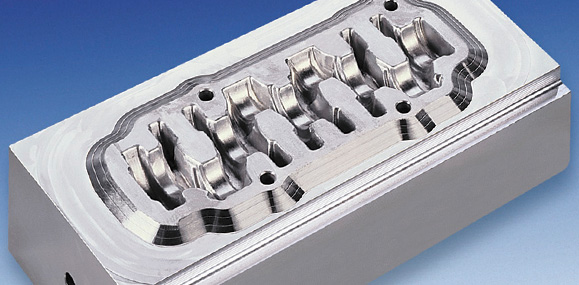

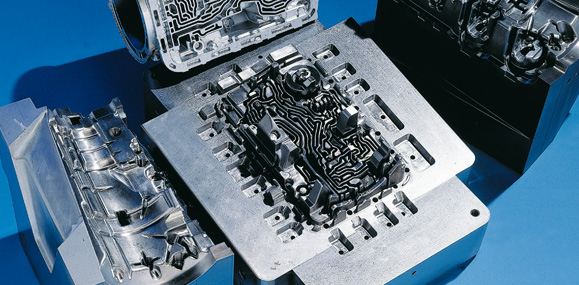

Steel TENASTEEL® better replaces the classic steel 1.2379 in all areas of its usage – tools for cutting and working of the metals, cutting of the aluminum, stainless steel, copper etc. It can be further used in the segment of steel treatment and recycling (knives, scissors ….). TENASTEEL® is very suitable for treatment of high-strength metal sheets, e.g. in the car industry.

Chemical composition of steel TENASTEEL®

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| TENASTEEL® | 1,00 | 0,35 | 7,50 | 2,60 | 0,30 | 250 | 62 | ||||||

Heat treatment of steel TENASTEEL®

| Way | Temperature [°C] | Procedure |

|---|---|---|

| Forging | For all the heat treatment of steel TENASTEEL® (P) we recommend the company BODYCOTE | |

| Soft annealing | ||

| Annealing to lower tension | ||

| Hardening | ||

| Tempering |

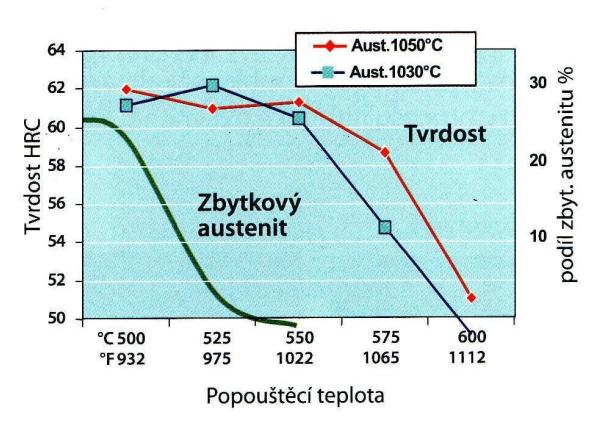

Tempering chart

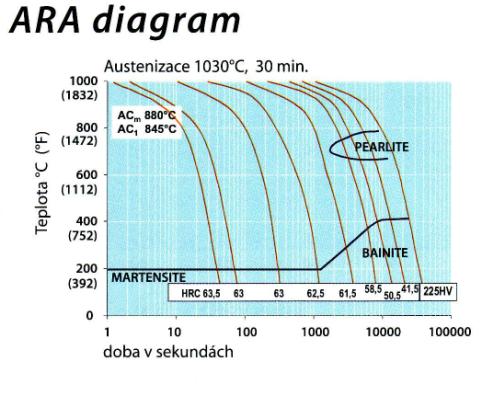

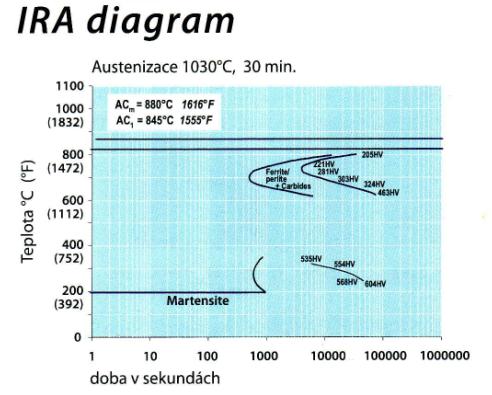

ARA and IRA chart

Product range

Blocks: 355x555

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.