W. NR. 1.2550

Characteristics

Chrome–tungsten–silicon–vanadium steel for cold work for hardening in oil with the middle hardenability (steel is hardened up to diameter of 60 mm during the hardening in oil), very high toughness, resistance to the dynamic stress, shocks and hits, good resistance to the wear and dimensional stability at the heat treatment.

Suitability

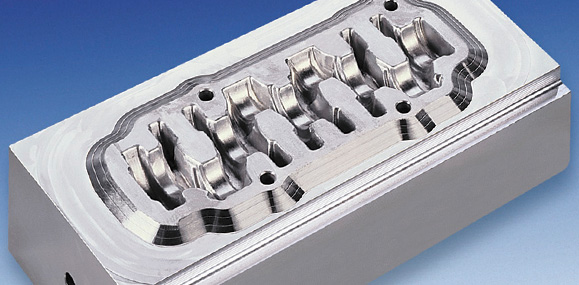

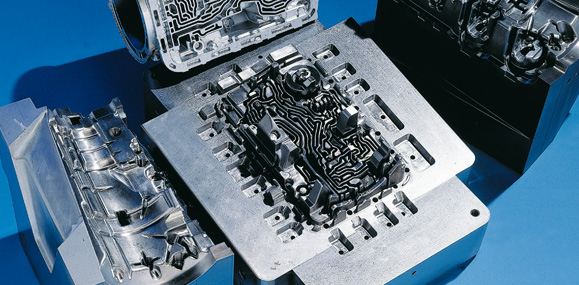

Tools for cold cutting, i.e. shear blades, tools for cold cutting and punching of materials of thicker thicknesses (up to about 15 mm) and higher hardness, profile and industrial knives, scrapping scissors, circular scissors. Tools for mechanical working such as tools for punching of simple as well as difficult shapes, tools for pushing and extrusion at lower pressures, marking dies, hammers, crusher for rougher crushing. Hand tools, i.e. pneumatic and hand chisels, marking dies for cold and also hot work.

Chemical composition of steel W.Nr. 1.2550

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN 60WCrV8 | 0,55-0,65 | 0,15-0,45 | 0,70-1,00 | 0,90-1,20 | 1,70-2,20 | 0,10-0,20 | 0,030 | 0,030 | 229 | 58 | |||

Heat treatment of steel W.Nr. 1.2550

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 850-1100 | Cool slowly in calm air or better e.g. in dry ash or other thermally-insulated material | |

| Soft annealing | 710-750 | Warm few hours (according to the size of object), mostly four hours are enough and cool slowly in the furnace | |

| 790-820 | For getting the minimum hardness and making the process faster, the temperature delay for about 2 hours and then slow cooling in the furnace from 50 °C/hour up to 500 °C | ||

| Annealing to lower tension | 600-650 | Warm 1 to 2 hours and cool slowly in the furnace | |

| Hardening in oil | 870-900 | Oil or hot bath 180-220 °C | |

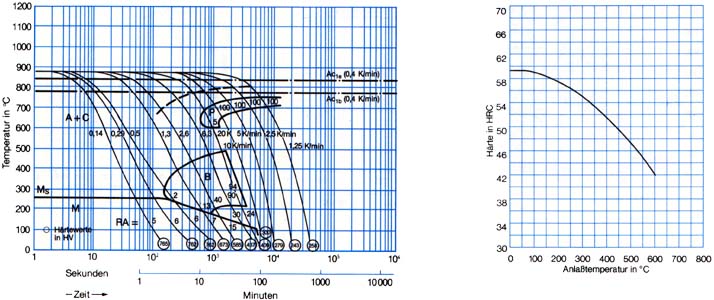

| Tempering | 180-400 | Cool in air, the degree of tempering is set by hardness and toughness of instrument according to the tempering chart | |

Note

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 60 | 58 | 56 | 52 | 48 | 43 |

Graph