Q10

CZK 0

Characteristics

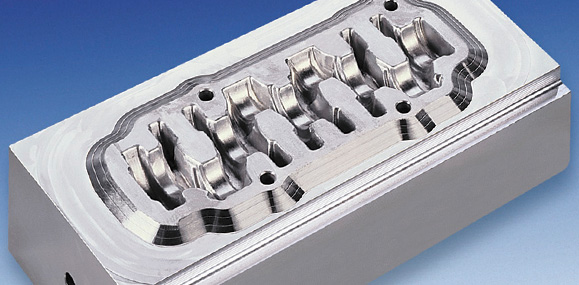

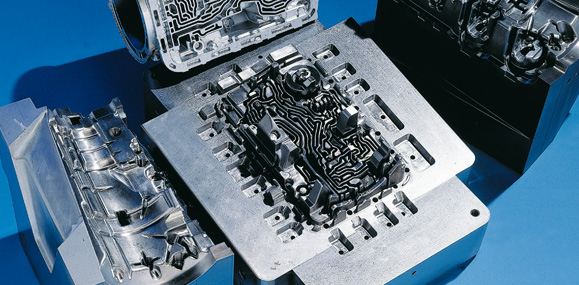

Tool steel Q10 is designed for stamping under the forging press. In comparison with classic qualities such as 1.2343, 1.2344, 1.2365, 1.2367 this material excels in the higher toughness, firmness during the heat and resistance to the hot abrasion. It is delivered in the soft-annealed state.

Suitability

Forging inserts for stamping under the press, extrusion tools, matrixes, holders of matrixes, thorns, tools for hot work.

Chemical composition of steel Q10

| Steel grade | Chemical composition in % | Hardness in state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| Q10 | 0,36 | 0,40 | 0,25 | 5,20 | 1,90 | 0,55 | |||||||

Heat treatment of steel Q10

| Way | Temperature [°C] | Procedure |

|---|---|---|

| Forging | For all the heat treatment of steel Q10 we recommend the company BODYCOTE. | |

| Soft annealing | ||

| Annealing to lower tension | ||

| Hardening | ||

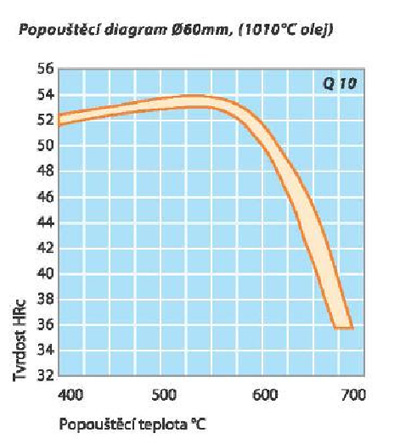

| Tempering |

Graph of tempering