W. NR. 1.2344 ESU

Characteristics

The chromium-molybdenum-vanadium-silicon steel is intended for oil quenching and air hardening. It has very good hardening capacity (the steel hardens over the whole cross-section to ca. 150 mm diameter), high hot strength and resistance to tempering and abrasion (higher than the 1.2343 steel), very good toughness and plastic properties at normal as well as high temperatures. The steel also shows very good resistance to cracks caused by thermal fatigue (lower than the 1.2343 steel) and higher sensitivity to abrupt temperature changes in comparison with the 1.2343 steel. The steel is suitable for heat treatment to strength exceeding 1765 N/mm2, and for water-cooled tools. It is thermoplastic and workable in soft-annealed condition.

Suitability

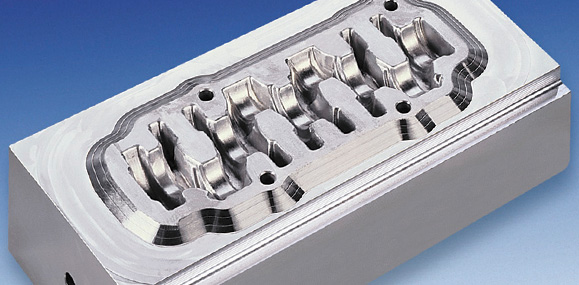

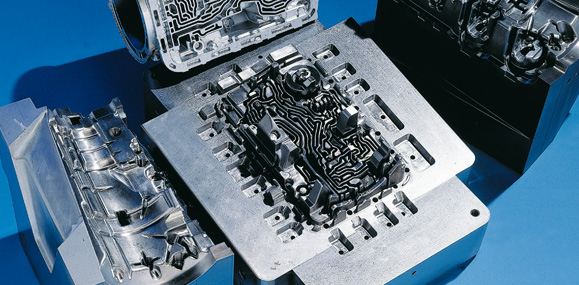

The steel is suitable for hot-forming tools like small dies for forging presses, counter-dies, die inserts, upsetting tools, piercing tools, jaws, and punches. It is also suitable for the hot extrusion of light-alloy components and for tolls subjected to high stress, for instance, die-casting moulds for aluminium and zinc, fixed and moving parts that come into contact with liquid metal, inserts of functional parts of mandrels, inlet sockets, slide valves, distributors, etc. The steel can also be used for hot-shearing tools, small and medium-size shear blades, trimming dies, and punching dies.

Chemical composition of steel W.Nr. 1.2344ESU

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN X40CrMoV51 | 0,37-0,43 | 0,30-0,50 | 0,90-1,20 | 4,80-5,50 | 1,20-1,50 | 0,90-1,10 | 0,030 | 0,030 | 229 | 51 | |||

| ČSN 19 554 | 0,34-044 | 0,20-0,50 | 0,80-1,20 | 4,80-5,80 | 1,10-1,60 | 0,80-1,20 | 0,030 | 0,030 | 250 | 51 | |||

Heat treatment of steel W.Nr. 1.2344ESU

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 900-1100 | Cool down slowly in dry ash or other heat-insulating material; large cross-sections should be cooled in a furnace | |

| Soft annealing | 750-800 | Heat up for several hours (according to the size of the object) – 4 hours are usually enough – and cool down slowly in a furnace | |

| Annealing to lower tension | 600-650 | Heat up for 1–2 hours and cool down slowly in a furnace | |

| Hardening | 1020-1070 | Smaller and simpler tools should be cooled down in oil to ca 100 °C and then removed to air | |

| Larger and more complex tools should be cooled down in the open air or in a 500–550 °C oil bath | |||

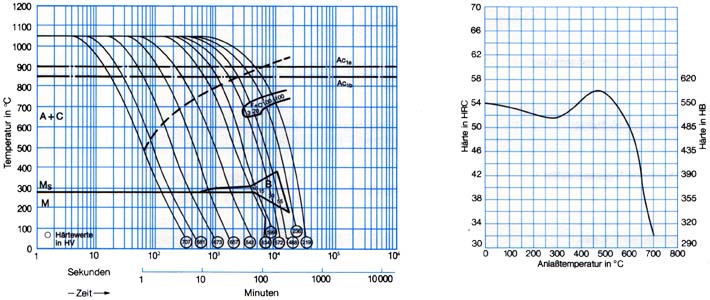

| Tempering | 550-650 | Cool down in the open air, the degree of tempering is governed by the tool’s hardness and toughness in accordance with the tempering diagram | |

Note

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

|---|---|---|---|---|---|---|---|---|---|

| HRC | 53 | 52 | 52 | 54 | 56 | 54 | 50 | 42 | 32 |

| N/mm2 | 1850 | 1790 | 1790 | 1910 | 2050 | 1910 | 1670 | 1330 | 1020 |

Graph

Delivery goods

Round bars: D102 - D605

Blocks: 410x1010, 510x910

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.