W. NR. 1.2365

Characteristics

Tool steel for hardening in air or in oil with very good hardenability, with high resistance to the tempering, very good firmness during the heat and very good toughness and also resistance to tearing in consequence of thermal fatigue. The steel has a low sensitivity to quick changes of temperatures and is mainly suitable for tools cooled by water. It is well-workable during the heat and well-workable in the soft-annealed state.

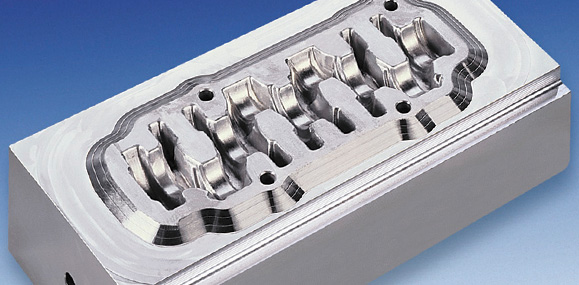

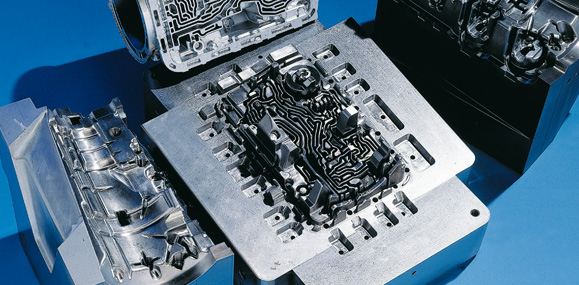

Suitability

For tools for mechanical working during the heat such as dies, die inserts, matrixes, jaws, punches, thorns, for tools cooled by water, automatic machines, for production of dies, screws, rivets, bearing rings etc., tools for extrusion of copper and its alloys, aluminum and its alloys in a large-lot production. Further the steel is appropriate for tools for hot cutting, for cutting thorns and trimming dies. The steel is also used for molds and their parts such as highly stressed firm and movable parts of molds, cores, sliders, distributors for pressure casting of products from copper and copper alloys or for a large-lot production of castings of a difficult shape from the aluminum and its alloys.

Chemical composition of steel W.Nr. 1.2365

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN X32CrMoV33 | 0,28-0,35 | 0,15-0,45 | 0,10-0,40 | 2,70-3,20 | 2,60-3,00 | 0,40-0,70 | 0,030 | 0,030 | 230 | 52 | |||

| ČSN 19 541 | 0,27-0,37 | 0,20-0,50 | 0,30-0,70 | 2,80-3,40 | 2,70-3,50 | 0,50-0,80 | 0,030 | 0,030 | 235 | 48 | |||

Heat treatment of stee W.Nr. 1.2365

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 850-1100 | Cool slowly in air or in dry ash or in other thermally-insulated material | |

| Soft annealing | 750-800 | Warm few hours (according to the size of object), mostly four hours are enough and cool slowly in the furnace | |

| Annealing to lower tension | 600-650 | Warm 1 to 2 hours and cool slowly in the furnace | |

| Hardening | 1020-1050 | Cool in oil or bath at the temperature of 500 – 550 °C | |

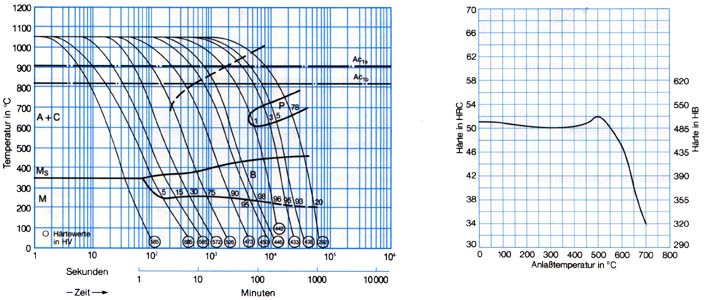

| Tempering | 560-670 | Cool in air, the degree of tempering is set by hardness and toughness of instrument according to the tempering chart | |

Note

- To lower deformations, especially at rugged tools, it is more appropriate to cool in hot bath or small tools in air.

- It is necessary to temper at least twice after hardening in hot bath or in air.

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

|---|---|---|---|---|---|---|---|---|---|

| HRC | 51 | 50 | 50 | 50 | 52 | 50 | 47 | 40 | 34 |

| N/mm2 | 1730 | 1670 | 1670 | 1670 | 1780 | 1670 | 1530 | 1260 | 1080 |

Graph

Product range

Round bars: D21 - D303

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.