TQ1

Characteristics

TQ 1 is an unalloyed Cr-Mo-V steel with very high toughness, firmness during the heat and resistance to the hot abrasion (higher than by other classic steels 1.2343, 1.2344, 1.2367). TQ 1 is produced only by ESU technology due to which the material has a high cleanness and a low content of trace elements. It is delivered in the soft-annealed state of max. 220 HB.

Suitability

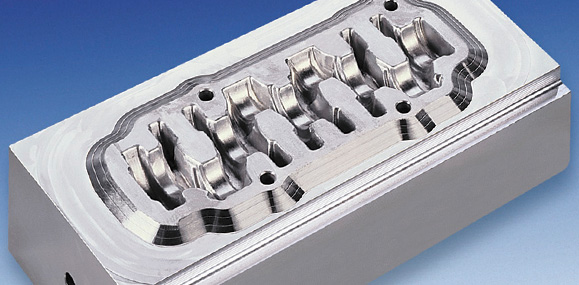

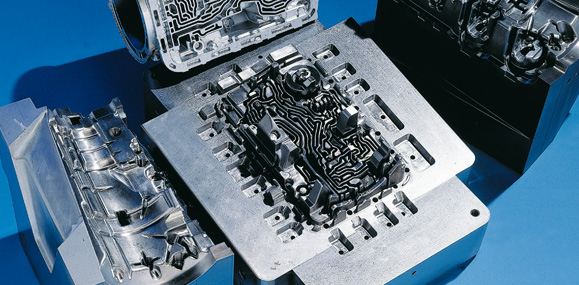

TQ 1 is appropriate for using in the following applications during a very high stress: pressure casting, extrusion, stamping, hot working. It is very appropriate for highly polished parts of molds (e.g. production of headlights etc.) due to ESU properties.

Chemical composition of steel TQ1

| Steel grade | Chemical composition in % | Hardness in state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| TQ1 | 0,36 | 0,40 | 0,25 | 5,20 | 1,90 | 0,55 | 220 | 54 | |||||

Heat treatment of steel TQ1

| Way | Temperature [°C] | Procedure |

|---|---|---|

| Forging | For all the heat treatment of steel TQ1 we recommend the company BODYCOTE | |

| Soft annealing | ||

| Annealing to lower tension | ||

| Hardening | ||

| Tempering |

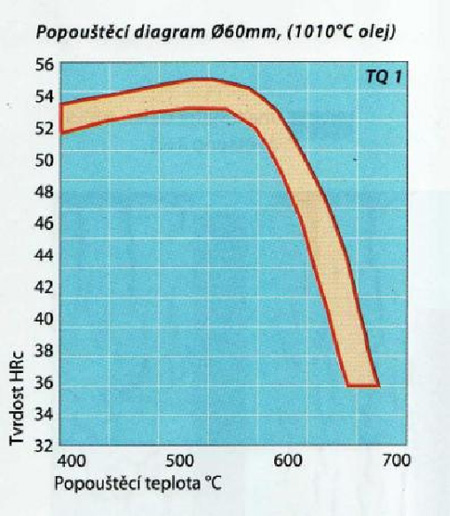

Tempering chart

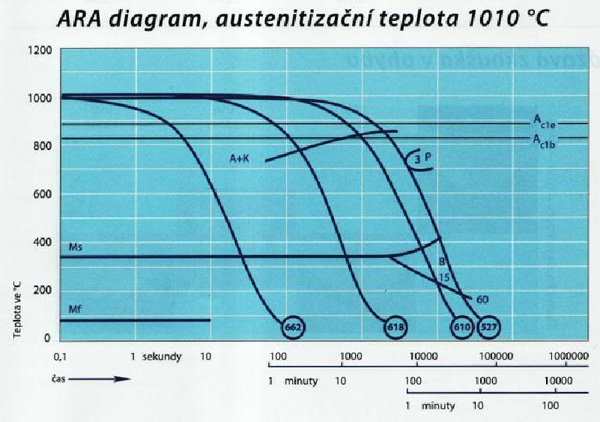

ARA chart

Product range

Round bars: D102 - D605

Blocks: 510x810

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.