CR7V-L

CZK 0

Characteristics and suitability of use

Special steel Cr, Mo and V alloyed . It is characterized by excellent wear resistance at very high temperatures. Thanks to its high toughness, it is resistant to breaking. Other advantages are very good machinability, hardness in the hardened state up to 57 HRC and the possibility of nitriding. Steel is ideal for use in both hot and cold applications.

Application:

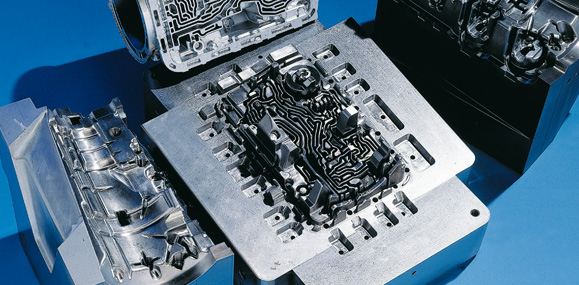

hot work - forging dies and die inserts for forging presses, hot forming tools (hot-stamping), extrusion dies, hot shearing blades

cold work - punches and shearing blades for sheet thicknesses of approximately 6 - 12 mm, rolls, former rolls, bending tools

Complete material data sheet for download

Chemical composition of steel Cr7V-L

| Steel grade | Chemical composition in % | Hardness | ||||||

|---|---|---|---|---|---|---|---|---|

| soft annealed | heat treated | |||||||

| C | Si | Mn | Cr | Mo | V | HB max. | HRC max. | |

| Cr7V-L | 0,42 | 0,50 | 0,40 | 6,50 | 1,30 | 0,80 | 240 | 57 |

Heat treatment of steel Cr7V-L

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Soft annealinng | 820-840 | with slow cooling in furnace | |

| Hardening | 1030-1040 | interrupt oil or polymer cooling at approx. 250 - 300 °C, or vacuum harden | |

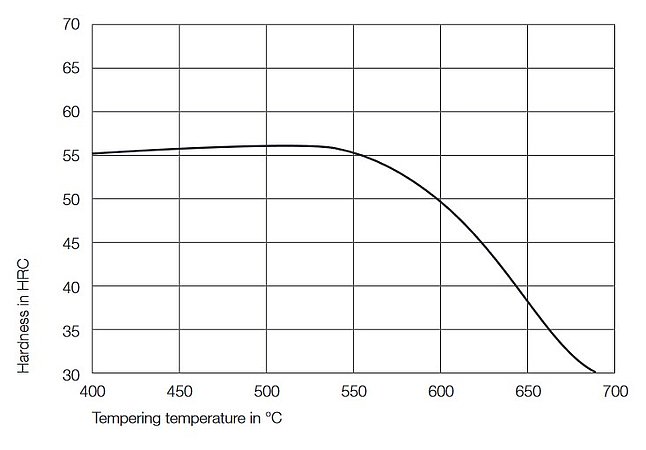

| Annealing | 500-700 | as needed, see tempering diagram, temper to increase toughness 2 - 3x | |

| Stress relieving | cca 650 | 2 - 4 hours with slow cooling | |

Graph