W. NR. 1.2085

CZK 0

Characteristics

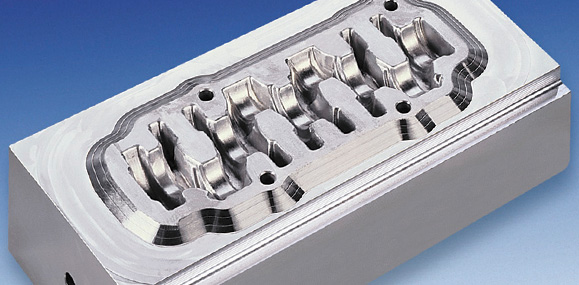

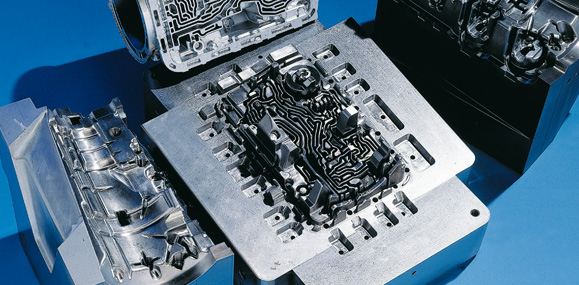

Resistant to the corrosion, Martensite steel with the high content of chrome. The steel has good resistance to the wear, good machinability and polishability. Delivered quenched and tempered 280 - 325 HB.

Suitability

Mould for pressing of chemically-aggressive plastic substances, corrosin-proof clamping frames of moulds etc.

Chemical composion of steel W.Nr. 1.2085

| Steel grade | Chemical composion in % | Hardness | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft annealed | heat treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN X33CrS16 | 0,28-0,38 | 1,40 | 1,00 | 15,00-17,00 | 1,00 | 0,030 | 0,030 | 230 | 48 | ||||

Heat treatment of steel W.Nr. 1.2085

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 800-1100 | Cool slowly in calm air or better e.g. in dry ash or other thermally-insulated material | |

| Normalization | 790-810 | Cool in air | |

| Soft annealing | 850-880 | War few hours (depending on the size), mostly 4 hours are enough and cool slowly in the furnace | |

| Stres annealing | 600-650 | Warm 1 to 2 hours and cool slowly in the furnace | |

| Hardening | 1000-1050 | Cool in oil or hot bath, the degree of tempering is set by hardness and toughness of instrument according to the tempering chart | |

| Tempering | 100-500 | ||

Note

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 |

|---|---|---|---|---|---|

| HRC | 48 | 48 | 47 | 46 | 47 |