W. NR. 1.2842

Characteristics

Manganese–chrome–vanadium steel with the middle hardenability for hardening in oil, particularly good dimensional stability at the heat treatment, good resistance to the wear and cutting power. Considerable sensitivity to cooling by water during the hardening and tempering, good polishability, good ductility at the heat and good workability in the annealed state.

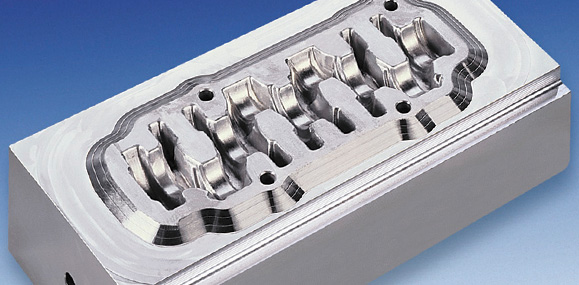

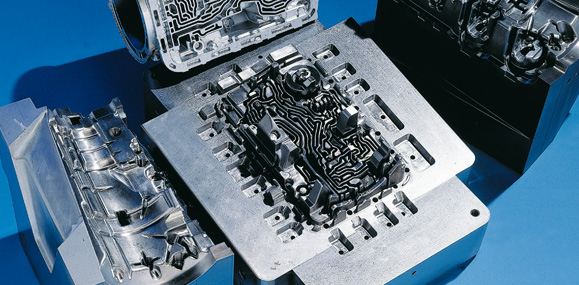

Suitability

Tools for cold cutting, i.e. all kinds of tools for cutting on presses and punching of materials of smaller thicknesses, especially difficult-shape punching dies and cutting punches requiring very good dimensional stability at the heat treatment. Shear blades for cutting of materials of smaller thicknesses, plate and disc knives for cutting of the paper etc. Tools for cold forging, i.e. tools for bending, rolling, drawing and punching of materials of smaller thicknesses. Small molds for working of plastics and rubber, less stressed molds for working of powder substances, porcelain and ceramic materials. Gauges of all kinds, rulers, conductive laths, patterns, calibres.

Chemical composition of steel W.Nr. 1.2842

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-trested | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN 90MnCrV8 | 0,85-0,95 | 1,90-2,10 | 0,10-0,40 | 0,20-0,50 | 0,05-0,15 | 0,030 | 0,030 | 220 | 58 | ||||

| ČSN 19 313 | 0,80-0,90 | 1,75-2,10 | 0,15-0,35 | 0,20-0,40 | 0,10-0,20 | 0,35 | 0,030 | 0,035 | 225 | 61 | |||

Heat treatment of steel W.Nr. 1.2842

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 850-1050 | Cool slowly in calm air or better e.g. in dry ash | |

| Soft annealing | 680-720 | Warm few hours (according to the size of object), mostly four hours are enough and cool slowly in the furnace | |

| Annealing to lower tension | 600-650 | Warm 1 to 2 hours and cool slowly in the furnace | |

| Hardening | 740-800 | Small objects | |

| 780-820 | Big objects | ||

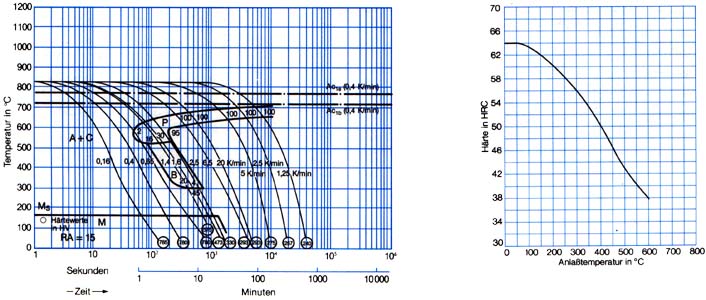

| Tempering | 150-250 | Cool in air (cannot get into the water!), the degree of tempering is set by hardness and toughness of instrument according to the tempering chart | |

Note

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 63 | 60 | 56 | 50 | 42 | 38 |

Graph

Product range

Round bars: D4 - D505

Sheets: s.1 - s.100

Blocks: 410x1010

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.