GSF

Characteristics

Nickel-chrome–molybdenum-vanadium steel GSF from the production of German steelworks KIND&Co heat-treated to the value of 1.350 Mpa. The steel has higher toughness and higher hardness during the heat than the classic steel W. Nr. 1.2714 while the resistance to the hot abrasion remained the same. Due to the already carried out heat treatment the production cycle of die can be shortened and the higher effectiveness of production can be reached.

Suitability

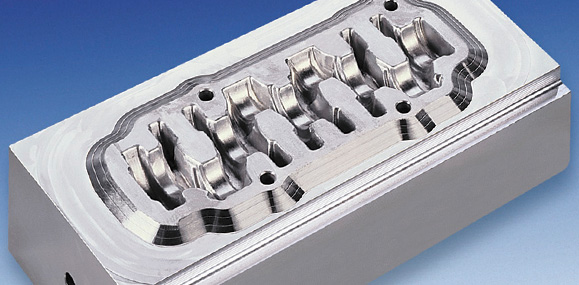

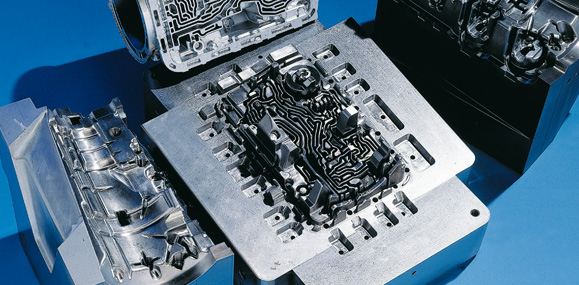

The steel GSF is appropriate for the production of forge tools, especially the dies under forging drop hammers.

Chemical composition of steel GSF

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| GSF | 0,28 | 0,70 | 0,30 | 2,80 | 0,60 | 0,40 | 1,00; | 43 | |||||

Heat treatment of steel GSF

| Way | Temperature [°C] | Procedure |

|---|---|---|

| Forging | For all the heat treatment of steel GSF we recommend the company BODYCOTE. | |

| Soft annealing | ||

| Annealing to lower tension | ||

| Hardening | ||

| Tempering |

Product range

Blocks: 325x720 , 275x820

The steel is already in the heat-treated state to the value of 1.350 MPa.

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.