Complete delivery including processing

We provide complete deliveries of machined parts in all commonly used materials. For this purpose, we utilize the latest CNC machining machines and technologies.

Contact us

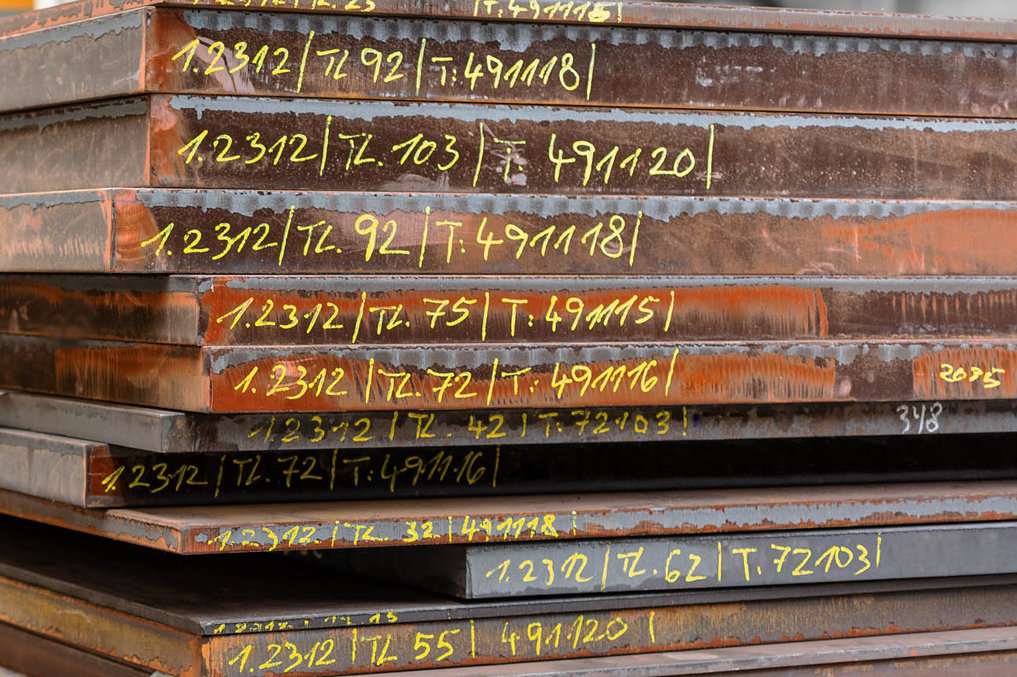

Logistics and Material Receiving

Pavel Smejkal jr.

Human Resources Department

Mgr. Jana Lábrová

M: +420 774 223 595

T: +420 517 306 121

E: jana.labrova@jkz.cz