W. NR. 1.2210

Characteristics

Chrome-vanadium steel with the middle hardenability for hardening in oil and water, relatively good toughness at the high hardness, good resistance to the wear and cutting power. More difficult ductility during the heat and good workability in the annealed state.

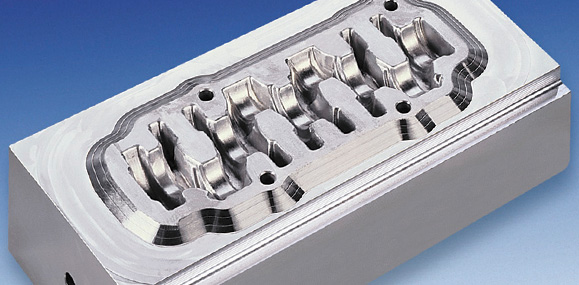

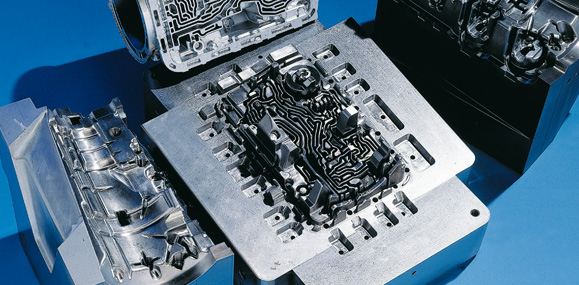

Suitability

Tools for cold cutting, i.e. cutting tools and punching tools, shear blades for cutting of materials of smaller thicknesses. Cutting tools for machining by smaller cutting speeds, e.g. drills, reamers, screw taps etc. Further for molds and auxiliary components, e.g. ejectors, pins etc.

Chemical composition of steel W.Nr. 1.2210

| Steel grade | Chemical composition in % | Hardness in the state | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| soft-annealed | heat-treated | ||||||||||||

| C | Mn | Si | Cr | W | Mo | V | Ni max | Co | P max. | S max. | HB max. | HRC min. | |

| DIN 115CrV3 | 1,10-1,25 | 0,20-0,40 | 0,15-0,30 | 0,50-0,80 | 0,07-0,12 | 0,030 | 0,030 | 223 | 60 | ||||

| ČSN 19 421 | 1,10-1,25 | 0,15-0,35 | 0,15-0,35 | 0,90-1,20 | 0,07-0,15 | 0,35 | 0,030 | 0,035 | 220 | 64 | |||

Heat treatment of steel W.Nr. 1.2210

| Way | Temperature [°C] | Procedure | |

|---|---|---|---|

| Forging | 800-1050 | Cool slowly in calm air or better e.g. in dry ash or other thermally-insulated material | |

| Soft annealing | 710-750 | Warm few hours (according to the size of object), mostly four hours are enough and cool slowly in furnace | |

| Annealing to lower tension | 600-650 | Warm 1 to 2 hours and cool slowly in the furnace | |

| Hardening | in water | 810-840 | Materials of thickness up to about 15 mm |

| in oil | 780-810 | Materials of thickness above about 15 mm | |

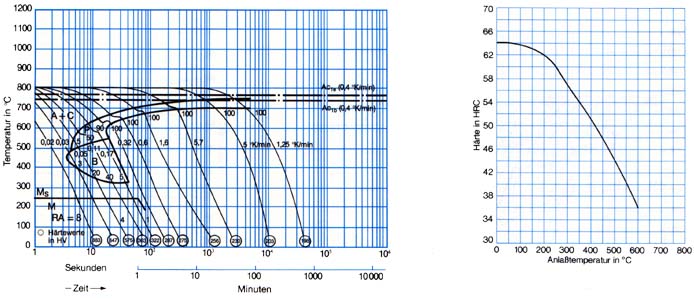

| Tempering | 180-250 | Cool in air, the degree of tempering is set by hardness and toughness of instrument according to the tempering chart | |

Note

Chart of tempering values depending on the hardness:

| °C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 64 | 62 | 57 | 51 | 44 | 36 |

Graph

Product range

Round bars: D2,5 - D25,5

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.